Goldsmith range is very wide and includes furnaces for professional use, suitable for melting of noble metals, cupellation and analysis.

GOLDSMITH FURNACES

GOLDSMITH FURNACES

• Kg 1-2-3 Ovens

• MZ Oven

• MSC Oven

• Z Oven

• ME Oven

• RH2-RH3 Ovens

• Z-C Oven

Electric furnaces made in Italy Prederi Vittorio and Sons

Goldsmith Furnaces

- Pit furnaces with crucible

- Cupellation

- Temperatures up to 1,350 degrees

• Kg 1-2-3 Furnaces (Metal casting)

The 1-2-3 Kg electric ovens are used in the goldsmith sector, specifically for melting, a process that consists in melting noble metals, such as gold and silver.

The 1-2-3 kg ovens quickly reach a temperature of 1150 ° C. Inside them it is possible to place a graphite crucible with a capacity (in specific weight) of the single metals of 1, 2 and 3 kg.

The ovens are complete with digital thermoregulator, graphite pliers and crucible, and, on request, with a heat protection grid and an analog thermoregulator.

• MZ Furnace (Enamels)

The MZ electric muffle furnace, of extremely reduced size and weight, is used in the goldsmith sector, specifically for gold and silver enamelling.

The MZ oven is heated on four sides by a muffle complete with resistors to ensure maximum temperature uniformity.

It is also finely painted and complete with digital thermoregulator.

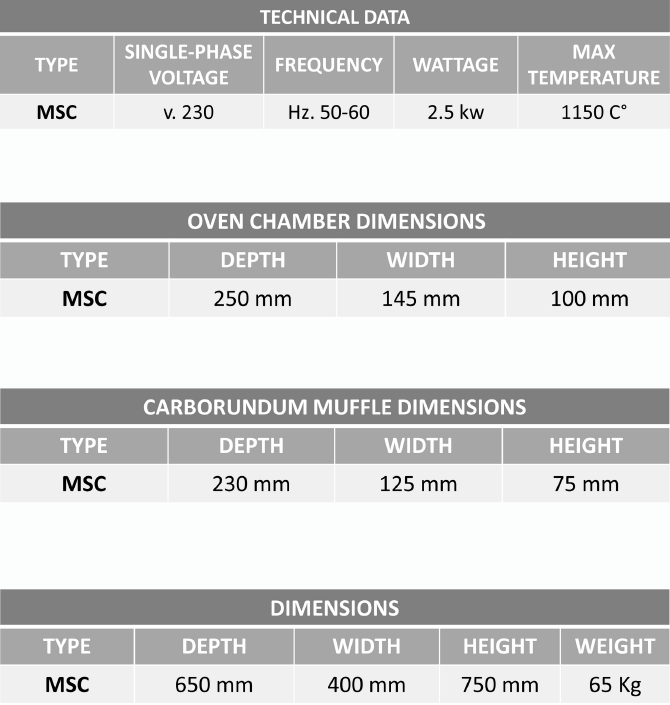

• MSC Furnace (Cupellation)

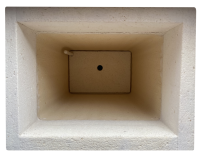

The MSC electric muffle furnace is used in the goldsmith sector, specifically for cupellation, a fundamental process that consists in refining and therefore separating noble metals, such as gold and silver from base metals present in minerals.

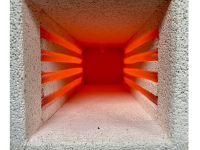

The MSC furnace is heated by a muffle complete with resistors. Inside it there is a removable carborundum muffle that can accommodate up to twelve cupels. The carborundum muffle is connected directly to the suction hood located on the upper part of the furnace, in order to absorb and eliminate the combustion vapors.

The oven is complete with a support shelf for the cupels, a digital thermoregulator, a daily or weekly timer on request, from which it is possible to set automatic switching on and off.

• Z Furnace (Annealing cylinders)

The Z electric muffle furnace is used in goldsmiths’ workshops, specifically for annealing cylinders, noble metals and their alloys.

The Z oven is heated on four sides by a muffle complete with resistances to ensure maximum temperature uniformity.

It is also finely painted and has various safety systems: microswitch and magnetothermic designed to protect the operator and the electrical system itself.

The oven is complete with a digital thermoregulator, a static unit and, on request, a temperature programmer, daily or weekly timer, from which it is possible to set automatic switching on and off.

• ME Furnace (Annealing cylinders)

The ME electric muffle furnace is used in goldsmith workshops, specifically for annealing cylinders, noble metals and their alloys.

The ME oven is heated on four sides by a muffle complete with resistances to ensure maximum temperature uniformity.

It is also finely painted and has a microswitch to protect the operator.

The oven is complete with a digital thermoregulator, a static unit and, on request, a temperature programmer, daily or weekly timer, from which it is possible to set automatic switching on and off.

• RH2-RH3 Furnaces (Metal casting)

The RH2 – RH3 electric silite rod ovens are used in the goldsmith sector, specifically for melting, a process that consists in melting noble metals, suchas gold and silver.

The RH2 – RH3 ovens are heated by silite rods, a technology that allows rapid heating of the chamber. Inside them it is possible to place a graphite crucible with a capacity (in specific weight) of the individual metals of 5 or10 kg.

The ovens are complete with digital thermoregulator, switch, voltmeter, ammeter and a set of 6 or 8 silite rods (5 kg, 10 kg).

Nose pliers and graphite crucible on request.

• Z-C Furnaces (Cupellation)

The Z-C electric muffle furnace is used in the goldsmith sector, specifically for cupellation, a fundamental process that consists in refining and therefore separating noble metals, such as gold and silver from base metalspresent in minerals.

The Z-C oven is heated by a muffle complete with resistors. Inside it there is a removable carborundum muffle that can accommodate up to eighteen cupels. The carborundum muffle is connected directly to the suction hood located on the upper part of the furnace, in order to absorb and eliminate the combustion vapors.

The oven is complete with a support shelf for the cupels, a digital thermoregulator, a daily or weekly timer on request, from which it is possible to set automatic switching on and off.